The PAT Family

PLATE ABSORBER TECHNOLOGY

PLATE ABSORBERTECHNOLOGY

PURE INNOVATION & TECHNOLOGY.

The patent that allows us to make a specially shaped horizontal tube that tapers off to become a single sheet of carbon. The result is amazing. Vibration is reduced by up to 18%, for greater comfort and safety. All without altering the rigidity required to ensure reactivity and racing performance.

Vibrations Absorbtion

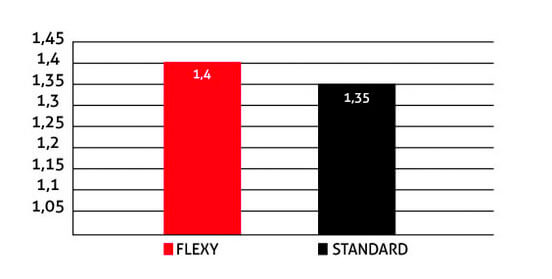

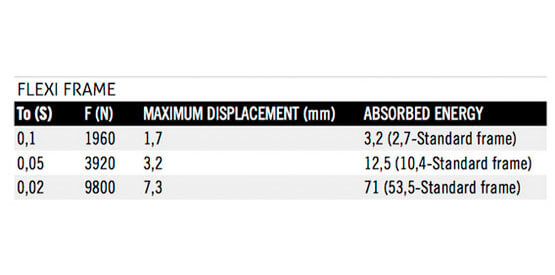

PERFORMANCE AND COMFORT. SCIENTIFICALLY PROVEN.

Comparative tests conducted by Parma University have demonstrated that the Flexy frame with P.A.T. technology absorbs up to 18% more vibrations than a standard frame. The energy generated by rough ground is dissipated so it has no effect on the cyclist’s hands and back.

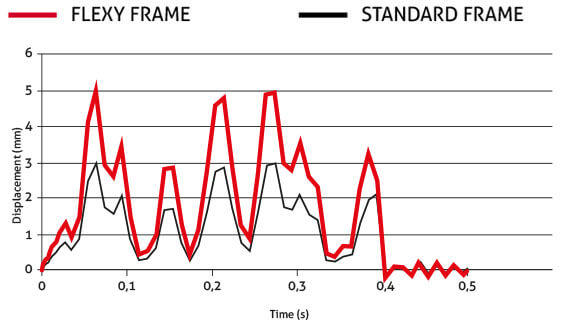

HIGH FREQUENCY

The graphics illustrate the greater vertical shift (that is, the increased capacity to absorb energy) of the Flexy frame under the solicitation of high frequency vibrations produced by irregular surfaces. In short: absolute comfort.

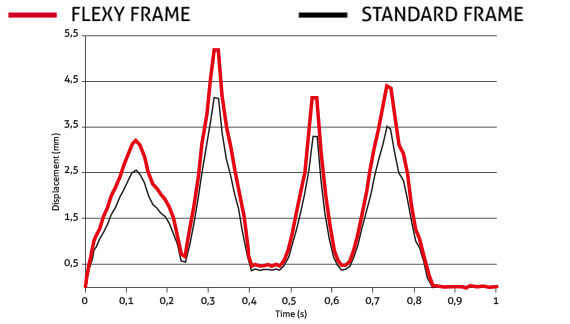

LOW FREQUENCY

The graphics illustrate the greater vertical shift (that is, the increased capacity to absorb energy) of the Flexy frame under the solicitation of high frequency vibrations produced by irregular surfaces. In short: absolute comfort.

VIBRATIONS ABSORPTIONS

HORIZONTAL RIGIDITY

THE FIRST PAT

After 3 years of study and many prototypes, the first PAT in the AWH (Anti Vibration Hole) version was born on the Xplosion frame, while in 2017 the first horizontal tube with a flat and ultra-thin shape (only 8 millimeters) saw the light, it absorb up to 18% more vibrations than a traditional frame, maintaining the torsional stiffness of the frame unchanged.

THE PRESENT

The development and continuous research on the horizontal tube led us to complete the PAT family in 2023, adapting it to horizontal tubes made of other materials, hence the birth of the PAT.P (Plate Absorber Technology Pressed) in collaboration with COLUMBUS on the steel and PAT.H (Plate Absorber Technology Hydroformed) in collaboration with DEDACCIAI on aluminum.

Furthermore, according to the new UCI frame tube thickness standard, the size of the carbon PAT tube has been redesigned to now reach a thickness of 10 millimeters, giving shape to the new PAT10, the thinnest in the world.

The modification allowed us to obtain the approval of the frame by the international federation, while maintaining its peculiar characteristics of performance, comfort, lightness and functionality.

NEW PAT10, UCI APPROVED

In the new VENTO model, the shape of the PAT tube has been redesigned according to the new UCI frame tube thickness standard. The modification allowed us to obtain the approval of the frame by the international federation, while maintaining its peculiar characteristics of performance, comfort, lightness and functionality. The top tube flattens out to now a thickness of 10 millimeters, the thinnest in the world. The particular shape allows the TITICI frame to absorb up to 18% of vibrations more than a standard frame without compromising torsional rigidity.

The irregularities of the asphalt are thus not transmitted to the arms and back of the cyclist, riding is more comfortable, precise, safe and stable. At the same time, the rigidity guarantees that the power expressed in pedaling is not dispersed, but transformed into outstanding responsiveness and performance.

NEW PAT10 MONOCOQUE, UCI APPROVED

In the ALFA model, the shape of the PAT tube has been redesigned according to the new UCI frame tube thickness standard. The modification allowed us to obtain the approval of the frame by the international federation, while maintaining its peculiar characteristics of performance, comfort, lightness and functionality.

The top tube flattens out to now a thickness of 10 millimeters, the thinnest in the world. The particular shape allows the TITICI frame to absorb up to 18% of vibrations more than a standard frame without compromising torsional rigidity.

The irregularities of the asphalt are thus not transmitted to the arms and back of the cyclist, riding is more comfortable, precise, safe and stable. At the same time, the rigidity guarantees that the power expressed in pedaling is not dispersed but transformed into outstanding responsiveness and performance.

PAT.P

The advantages of PAT.P technology (Plate Absorber Technology Pressed) are superior stability and comfort, associated with high performance.

The vibrations generated by uneven terrain are absorbed by the frame structure, they do not reach the cyclist’s arms, neck and back, the areas typically most stressed, thus resulting in a greater sensation of well-being in the saddle over long distances.

Furthermore, the lateral rib of the tube gives it the right lateral stiffness and prevents the frame from bending when pushed.

PATH.H

The main innovation concerns the top tube featuring the new PAT.H (Plate Absorber Technology Hydroformed) technology, derived from the patented PAT system available on TITICI carbon frames. The iconic shape with an oval section, which is thinner and flatter, increases the vibration damping capacity while maintaining high resistance and torsional rigidity. The top tube is given this shape through hydroforming, a technique also used in the production of sports cars that exploits the high pressure of liquids to create extremely reliable and resistant tubes.

The benefits of PAT.H technology are superior stability and comfort combined with high performance. Vibrations generated by uneven terrain are absorbed by the frame structure and do not reach the rider’s arms, neck and back, the areas typically subjected to the most stress, thus leading to a greater feeling of well-being in the saddle over long distances.