Sam William Andrews Diary: #2 Badlands Granada -Spain

Jesse Yates and I embarked on this journey with a single goal at the beginning of the year: to win the pairs category and secure a spot in the top 10.

This race is infamous for its scorching heat, but we were fortunate to encounter storms and cooler temperatures, something we didn’t stress about, coming from the UK.

Our game plan was to maintain a consistent pace throughout the race. The start was intense, but we knew not everyone could sustain that speed. As night fell, we steadily overtook riders left and right, comfortably securing a position in the top 10 overall. We battled fiercely for the pairs position, sometimes wondering if first place was within reach.

Upon reaching Almería, we pushed hard up the climbs, creating a substantial gap between us and the pursuing pairs.

The last 100km proved to be the most grueling challenge I’ve ever faced. I experienced hallucinations, struggled to stay awake on my bike, and felt disoriented.

Crossing that finish line was an emotional triumph. We achieved our goal, rode efficiency, and the relief of finally completing this arduous journey was overwhelming.

See you out there!

Deux mille Challenge: MAX DID IT!

Maximillian Schnell did it! All 204 cols over 2,000 meters in the Pyrenees and Alps in 77 days, self-supported, with no rest days: 10,839 kilometers and 271,004 vertical meters.

He’s the first person ever to accomplish this, at his side a special edition of our Sterrato, a gravel bike made with custom Columbus steel tubing.

It all started on 27 May 2023 in Luz-Saint-Sauveur in the French Pyrenees, where a small group joined Max at the beautiful Pont Napoleon. Col des Tentes was the first col to be conquered. The Pyrenees showed their best and worst sides; the immaculate sceneries mixed with springtime weather, where sunny conditions would change the rain and hail, typically in the afternoons. It was a rough start for Max, who had to get up in the middle of nights to catch up on lost time. In eight days, Max had ticked off all 24 cols in the Pyrenees and could make his way towards the Alps.

The weather wasn’t much better in the southern Alps. The pattern stayed the same for days. Rideable mornings, rain in the afternoons. The highest top in the challenge, Cime de la Bonette, hadn’t been cleared of snow and Max had to hike the last 300 meters to the top.

During the planning phase, which started ten months ago, we put much effort into getting every paved col on the list. The community was a huge help. Our definition of a Deux Mille col is paved from start to finish, which is 1) a pass, 2) a dead-end, or 3) a significant end-point, e.g. a ski resort or a restaurant. Still, within these boundaries, it gets blurry. Some cols were included, but we weren’t sure if they met the criteria. If in doubt, Max would do them anyhow. In the end, of the 204 cols conquered, 198 met the criteria.

Not surprisingly, some of the best moments came from lesser-known climbs, like Cirque du Troumouse, Les Fonts, Lago del Naret, Lago della Sella, Steingletscher, Oberaarsee, and Petit-Mont-Cenis. Especially in the world of bike packers, where Max excels, these cols bring something unique to the table.

Summer finally arrived and through France and Italy, time was gained. Some tricky changes kicked in around the normally ever-so-beautiful Dolomites, where the weather turned bad again and the challenge entered Austria. The Austrian cols were, pretty much without any exceptions, incredibly tough. However, Max’s friend, and triathlete, Flo Mestdagh joined (on his tri-bike) and rode with Max for the remainder of the challenge. At the Tiefenbachferner, the challenge reached its highest point (but the col ends lower.) The mighty Tiefenbach, and the linked Rettenbach, were disappointingly fake.

Perhaps the hardest day was 26 July, when winter conditions halfway up the Grimselpass, kept Max and Flo grounded for hours, and Max got concerned about his health. He couldn’t keep himself warm, and ignoring the signals would only make things worse. Time was lost. Faced with hard weather conditions at the start of the week, and suddenly running behind schedule, it became “either you follow me, or I don’t wait for you” for Max and his friend Flo. But also day 35, in the Dolomites, with 12 hours of riding, 203 kilometers and more than 6,600 vertical meters gained was brutal.

A Forrest Gump-like trend started during the last 2-3 weeks of the challenge. More and more, especially bike packers, joined Max, and by the time they did the final Italian climb, Col du Petit Saint Bernard, a group of up to 15 was riding with Max. The group increased all the way to the penultimate climb up to Col du Galibier, where both riders, family, and friends at the top, celebrated the historic accomplishment on 12 August.

@deuxmillecc , @maxschnell555

source: https://www.deuxmille.cc/challenge

Discover more

Sterrato GRX Silver LE

€ 5.990,00Sterrato

€ 2.990,00 – € 5.690,00Columbus x TITICI - Heart of Metal

Columbus x TITICI – Heart of Metal

Read the Columbus’ interview to Matteo Pedrazzani, TITICI Product Manager. Discover more about road model Strada, Progetto Sessanta and the collaboration with Columbus technicians.

SICILY BIKEPACKING GRAVEL XPERIENCE

Sicily, land of the Normans, a land of sea and mountains, volcanoes, and green pastures. The land of my family.

A land of sun, but also of mud, that mud which made my journey difficult. Mud that, in some cases, literally stopped me. Seven days on my TITICI RELLI, carrying only the essentials, I crossed the coasts and the hinterland of this stunning island solo.

On my bike, I felt simultaneously in Ireland for its green coasts, in Cambodia for its muddy and bamboo-filled interior, in Africa for the climate and arid zones, and in Italy for the people and the food.

I covered a distance of 800 kilometers in seven days of pedaling, with an elevation gain of 12,000 meters, mostly tackling the inland areas. It was there that I witnessed the most beautiful landscapes, going from the coast to the pastures of Mount Etna Park, reaching out to touch the imposing Valley of the Temples in Agrigento. Modica, known as the city of a hundred churches, Syracuse, a city of Greek origin.

I saw the breathtaking white Scala dei Turchi. I savored the food and the hospitality of its inhabitants (thanks to those who decided to host me).

Once again, I did it my way… solo. They ask me, “Why do you travel alone?” Traveling alone is a journey of double value for me… you taste everything you encounter around you, but you have to face everything that is within you.

Find the courage to embark on this kind of experience… it will leave an indelible mark and unforgettable memories, and perhaps choose Italy as your first journey… it won’t disappoint you.

BON VOYAGE TO ALL.

Eurobike Frankfurt here we come!

Eurobike Frankfurt here we come!

During the fair, we will present our new TITICI bicycle collection, which stands out for its technological innovation, attractive design and superior performance. We will be happy to show the new models and to discuss the unique characteristics of each product to the cycling industry people.

Some models have already been presented through the launch on social media, such as the new Vento and the Strada and Sterrato steel frames, while we will have 2 absolute novelties, both carbon monocoque frames, one is the road aero version with stunning design, the ALFA model and the second a gravel all-round, the REVO, equipped with the new Sram Apex AXS group set.

We will wait for you at Hall 11 Stand D11!

ALFA

ALFA, like the first letter of the Greek alphabet α, symbol of ‘beginning’. The beginning of a new era of hypersonic design and disruptive innovation of current aerodynamic standards.

Since 1961 TITICI has been synonymous with Italian genius and avant-garde spirit. Our philosophy requires us that each new model represents a real innovation, something that did not exist before. From this tradition of innovating comes a new standard of aerodynamics applied to speed, the ALFA project.

ALFA represents our fastest racing bike ever, born starting from the brand new PAT10 tube, which pushes the boundaries of the possible thanks to a triple approach: unprecedented aerodynamics, exceptional ride quality and design characterized by fluid shapes. This racing bike is equipped with the unprecedented DAC TECHNOLOGY, which offers the maximum advantage in terms of speed, stiffness and comfort.

A racing bike with unprecedented aerodynamics!

REVO

REVO represents our All-round gravel carbon bicycle, with a functional and compact design, built around the new monocoque PAT10 tube, to be used for training or competition, solo travel or for outings close to home with friends.

The REVO frame is made of monocoque carbon, compatible with single chainring groupsets or with double crankset, both electronic and mechanical, and offers exceptional versatility and flexibility to cyclists who choose it for their off-road adventures.

A gravel bike with no limits!

VENTO

The new VENTO, the TITICI lightweight climbing bike, now UCI legal. Starting from 1961 we always fight to introduce new innovation in function and design, using the Italian creativity. We never stop in front of rules or competitors’ comments. But when the UCI changed the dimensions tubing for the road bike frames, we understood that maybe the Swiss technicians found our PAT so interesting that should be make legal.

We worked hard on the existing PAT, new shape, new lamination, new carbon blend and, after 2 years, we are proud to launch the new PA , now 10 mm thick to the new Vento.

Handmade to measure in Italy, entirely customizable from geometry down to paint job , extraordinarily pleasant to ride: both on the legendary Alpine passes and on the fast stretches on the flat.

Less weight, more stiffness, same comfort! A new era for your road riding experience!

Discover more

Progetto Sessanta - Steel is real

S like SESSANTA, the years of life of TITICI.

S for STEEL, in English, a noble material rich in history in the bicycle frame production sector.

With PROGETTO SESSANTA, TITICI wants to celebrate the heritage of steel processing, revisited in a modern key. Tradition and technology, art and Italian craftsmanship of a material that for decades has been skillfully worked at the Castelnuovo di Asola plant, to create hand-welded frames and shipped all over the world, before being set aside for more modern materials such as aluminum, titanium and carbon fiber.

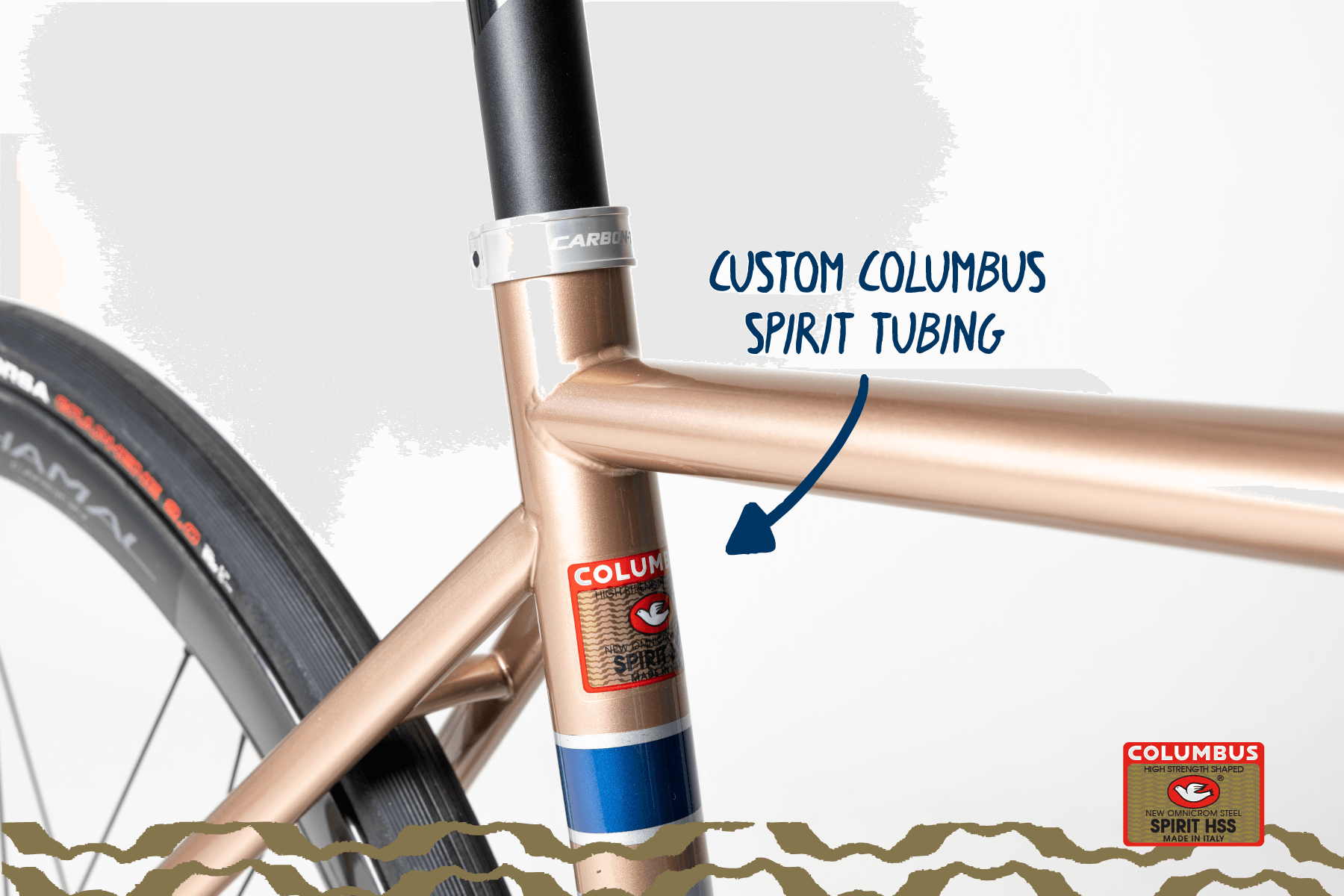

In recent times, steel has been rediscovering a new life, above all thanks to the growth of the gravel and adventure bike segments, which prefer frames made with this material, robust, soft and alive, which speaks to the frame builder who builds it and to the cyclist who uses it.

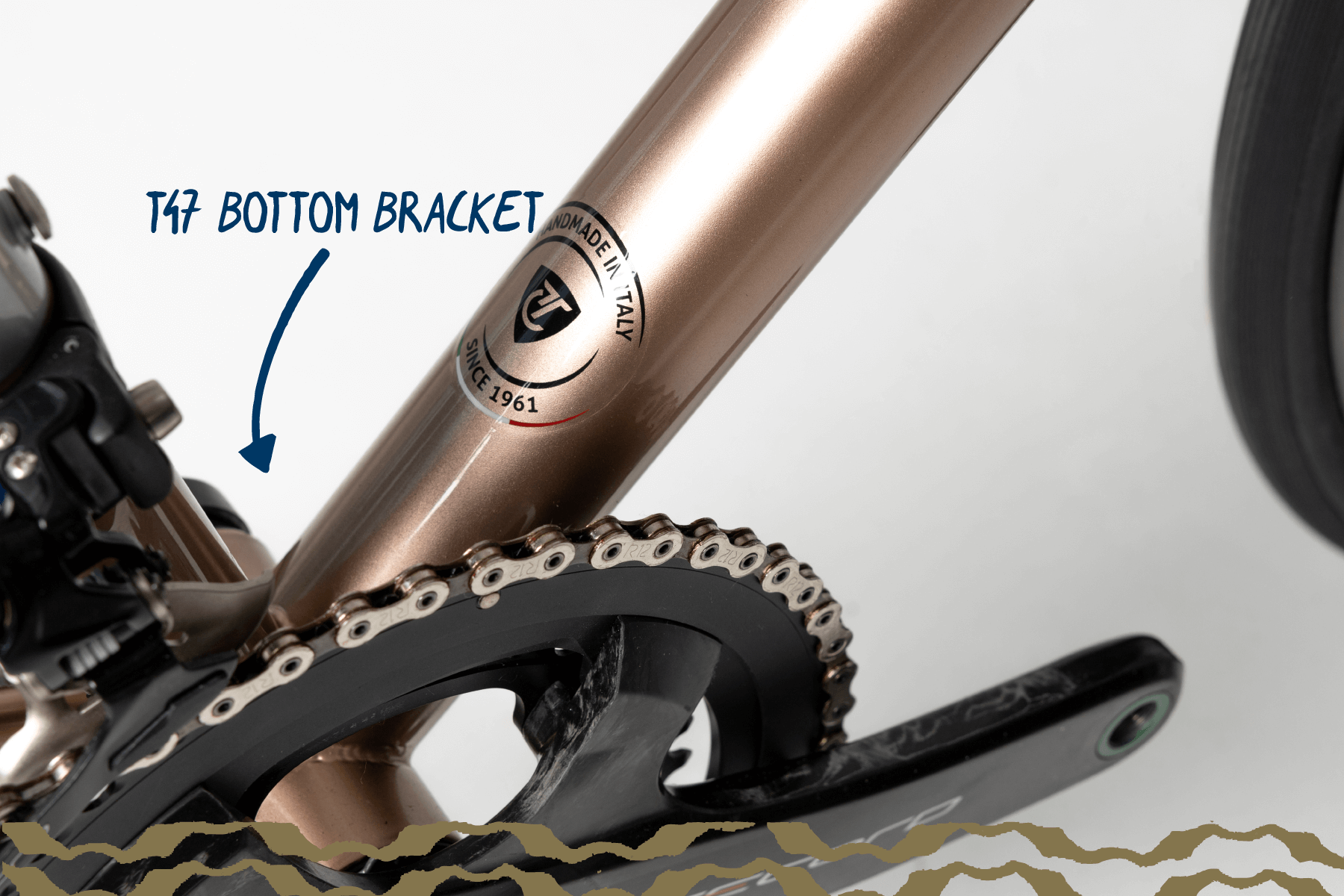

PROGETTO SESSANTA makes it possible to revive an entirely “Made in Italy” collaboration with Columbus, the historic company from Caleppio di Settala (Milan), world leader in the production of high-end steel tubes for craftsmen and frame makers, preferential supplier of the noble material for many years.

The PROGETTO SESSANTA is the result of two years of development and work between the TITICI engineers and the Columbus technicians, to produce special exclusively designed tubes, to be used for the construction of a specific frame for gravel, called STERRATO, and one for the road segment, called STRADA.

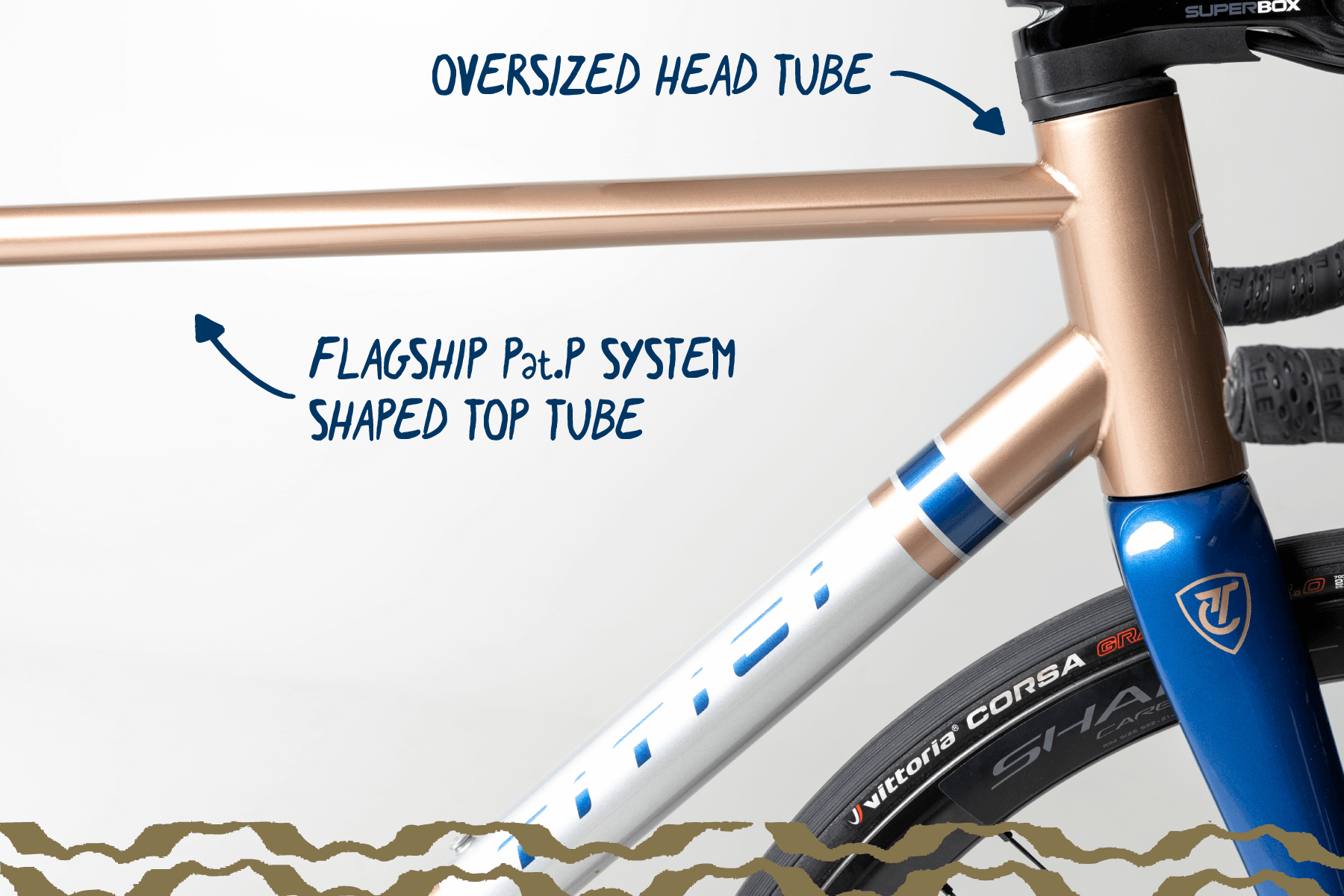

In particular, the top tube presents the classic TITICI shape of the PAT (Plate Absorber Technology) system used on carbon frames, which in the case of steel is completed in PAT.P (Plate Absorber Technology Pressed). The flat and thin shape of the flattened tube helps to reduce vibrations without compromising the rigidity and frame performance.

STRADA and STERRATO, the perfect union of Italian tradition and innovation.

Discover more

THE TRAKA DIARY

It was a weekend full of emotions and experiences for the TITICI CREW at The Traka in Girona. Super congratulations to @samwilliamandrews for hitting the top ten in the 360k course, an incredible 6th position on his RELLI GHOTIC SHADOW.

Applause to the guys of the @sartoriaciclistica TITICI GRAVEL TEAM team, to @ubycyclist, @federicovandone, @sambylord, @and_gini72, @federico_pallanch, who, on their TITICI bikes, participated and completed the 360k, 200k and 100k routes.

A special thanks to @tdtorre and @javiangulog from the magazine @rawcyclingmag, who shared days of laughs, interviews, photo shoots and lots of dust in the race with the TITICI CREW! THE TRAKA see you next year!

Sam William Andrews Diary: #1 BWR Arizona - US

I embarked on a grand desert escapade to Arizona,

all in the name of kick starting my season with a bang at the Belgian Waffle Ride.

The course was a tantalizing blend of treacherous terrain, featuring undulating hills, specially designed MTB trails, rugged sand washes, and bumpy 4×4 roads.

And all of this set against a picturesque backdrop of the stunning desert rock and prickly cacti.

The course, spanning 122-miles, was a perfect medley, making it the ideal prelude to a long season ahead.

With the 7am start fast approaching, I found myself at the front of the start line, flanked by ex-world tour pros, national champions, Olympians, conti riders, and weekend warriors.

The atmosphere was electric, and everyone was eager to prove their worth after months of grueling winter training.

As we set off on a neutral roll out, we were almost immediately faced with a long, grueling climb.

At first, it was a peaceful ascent with friendly chatter, but soon after, the pace intensified, Pete Stetina led the charge up the steep inclines.

Despite my best efforts, I found myself in the second chasing group, struggling to keep up with the lead pack.

However, as soon as we hit the first off-road sector, I kicked into high gear, determined to make up lost ground and tackle the challenging terrain with all my might.

The race was not without its obstacles, but I dug deep and persevered, never giving up.

And as I crossed the finish line, I was elated to have secured a top 30 overall finish and a top 20 spot in my age category.

It was a grueling yet rewarding experience, and I can’t wait for more of it this season.

See you out there!

Titici Alloi, an endless adventure

The Italian brand introduces the third generation of the Dedacciai aluminium gravel model designed for bikepacking and fun on dirt roads. With new PAT.H. system for vibration damping and superior riding comfort

In 2020 TITICI presents the A-GR01, its first gravel model with Dedacciai aluminium frame. The following year from the hub of Asola (Mantua Province, Italy) comes ALL-IN, the evolution of the predecessor, with integrated cable routing, new frame and rear triangle geometries. Now the Italian brand is ready to launch ALLOI, the third generation in its family of aluminium gravel bikes. The DNA has remained the same: adventure, travel, fun – with no limits in terms of duration or terrain.

New PAT.H. anti-vibration technology, comfort and resistance together

Faithful to the ‘family’ tradition, the ALLOI frame also stems from the collaboration with Dedacciai, the leading Italian company that produced the highest quality aluminium tubes, with handmade welds and customised shapes for TITICI.

The main innovation concerns the top tube featuring the new PAT.H (Plate Absorber Technology Hydroformed) technology, derived from the patented PAT system available on TITICI carbon frames. The iconic shape with an oval section, which is thinner and flatter, increases the vibration damping capacity while maintaining high resistance and torsional rigidity. The top tube is given this shape through hydroforming, a technique also used in the production of sports cars that exploits the high pressure of liquids to create extremely reliable and resistant tubes.

The benefits of PAT.H technology are superior stability and comfort combined with high performance. Vibrations generated by uneven terrain are absorbed by the frame structure and do not reach the rider’s arms, neck and back, the areas typically subjected to the most stress, thus leading to a greater feeling of well-being in the saddle over long distances.

Redesigned fork for improved ride stability

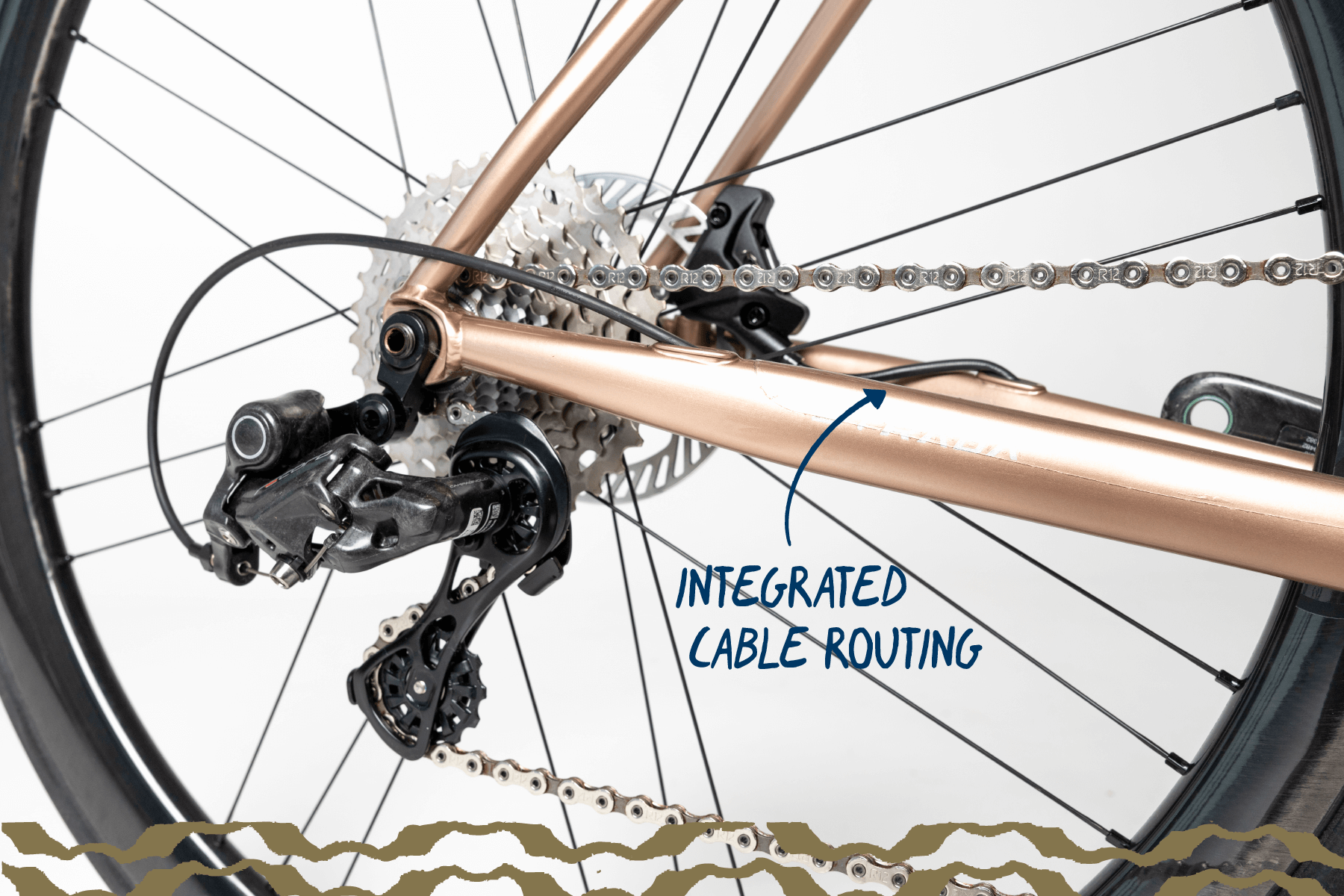

Like on the ALL-IN model, the head tube features an oversized diameter of 1 1/2″ that allows for full integration of the cables. TITICI engineers have completely redesigned the fork with an accentuated asymmetry to counteract the forces produced by the braking system. The result is greater riding stability on the most technical terrain.

Made in Italy design and functionality

Designed for long off-road adventures, the ALLOI model is optimised in every aspect, from its bikepacking predisposition to the possibility of fitting generously sized tyres, up to 700c x 40 or 650b x 45, and tackling the most extreme trails with full confidence. Sophisticated details make it unique and exclusive: the chiselled and hand-painted Titici logo on the seat stay bridge and on the chainstays, the graphic pattern on the top tube that evokes the magic of dirt roads, the total customisation of the colours. A perfect union of Made in Italy design and innovative functionality that has always been the hallmark of TITICI.

Premiere at Cyclingworld Europe in Dusseldorf, available now

It is possible to discover ALLOI in world premiere at the Cycling World Europe fair in Dusseldorf, Germany, from 10 to 12 March. The new TITICI bike model is available now on the official website www.titici.com.

The e-gravel in disguise - TITICI presents DYNAMICA.

Premiering at the Italian Bike Festival in Misano Adriatico (Sept. 9-11), the Italian brand’s new e-bike with an innovative Mahle X20 drive unit. Light, compact and streamlined: a gravel bike with extra muscle power!

The new DYNAMICA gravel bike is Titici’s all-new gravel bike with grit infused into its DNA. A substantial amount of engineering research was put into the integration of the frame with the Mahle X20 system, a powerful and innovative drive unit.

DYNAMICA is a bike designed for performance: on the flat, it’s fast and light, even without assistance above 25 km/h; and on climbs or more technical sections, the Mahle X20 motor delivers power smoothly and naturally. Enjoy longer rides, more hours in the saddle, and more fun!

Compact and sleek design: as if there was even a motor.

A key aspect of the DYNAMICA is the evolution of chassis design. TITICI engineers have succeeded in creating streamlined and compact shapes, taking chassis-drive unit integration to an entirely new level.

One example is the small bottom bracket and streamlined, aerodynamic down tube designed to accommodate a 350 Wh battery (the largest offered by Mahle). The motor in the rear hub contributes to a cleaner, more harmonious aesthetic line.

PAT anti-vibration technology.

With its patented PAT (Plate Absorber Technology) design, the DYNAMICA frame is designed to handle rough terrain as well as roads. The flat, slim shape of the top tube provides a vibration-reducing effect (up to 18% more than a standard frame) while maintaining high torsional stiffness. This results in racing performance combined with increased comfort.

Redesigned fork, superior strength.

The head tube with an enlarged 1 1/2-inch cross-section allows full integration of cables for a clean aesthetic, while at the same time providing superior riding stability, especially on technical downhill sections. TITICI engineers redesigned the fork with an accentuated asymmetry to counteract the forces generated by the braking system. A particular angle is designed into the left chainstay for greater resistance at the disc brake caliper.

More stability, and more responsiveness with the new rear carriage.

The rear triangle has also been redesigned to provide an outstanding riding experience on rough terrain. Rather than joining the seat tube, the seat stays continue to engage the top tube. In a strategic area of the frame where forces are concentrated, this design creates a more stable and strong node. The shortened chainstays provide better handling, while the asymmetrical design offers more traction. The frame is designed to accommodate generously sized tires, up to 700c x 44 or 650b x 48, and tackle the most extreme trails with maximum fun.

Mahle X20, the lightest system on the market

X20 is the new drive unit from Germany’s leading automotive and smart mobility company. Weighing only 3.2 kg, X20 is the lightest hub-integrated system on the market. At the same time, power is not to be desired: with a torque of 55 Nm, pedaling is smooth and natural on any terrain. Even when speeds exceed 25 km/h, the Mahle X20 system eliminates the typical resistance felt with less advanced systems.

The 350 Wh battery is housed in the down tube, and a 172 Wh Range Extender can be added (in place of the bottle cage) to achieve a maximum range of 200 km. Smart charging allows you to recharge the battery to 80 percent in less than two hours and get back to blazing on the trails.

Premiering at the Italian Bike Festival Sept. 9-11

The new TITICI DYNAMICA Gravel will be unveiled for the first time at the Italian Bike Festival, Italy’s largest bicycle trade show, scheduled for September 9-11 at the Misano World Circuit in Misano Adriatico (RN).

Available also in Road version, delivery will begin in spring 2023. Order now.