REVO bike tested by Raw Cycling Magazine

REVO bike tested by Raw Cycling Magazine

We delivered a REVO bike with Campagnolo Ekar setup to the Spanish magazine RAW Cycling for a long-term test during THE TRAKA event in Girona. After 3 months of testing on the gravel trails of Catalonia, the testers expressed themselves very positively and fully understood the versatility characteristics of the new TITICI gravel model. To read the detailed test result you can click on the following link.

Discover the product

Titici Alloi AND, the AND is back!

After the success of ALL-IN AND, the anodizing process on TITICI aluminum returns by popular demand on the ALLOI model. To set up the complete bike, we decided to use a cassette and crankset handmade in Italy by INGRID. A perfect combination of Italian creativity and know-how!

The return of anodized

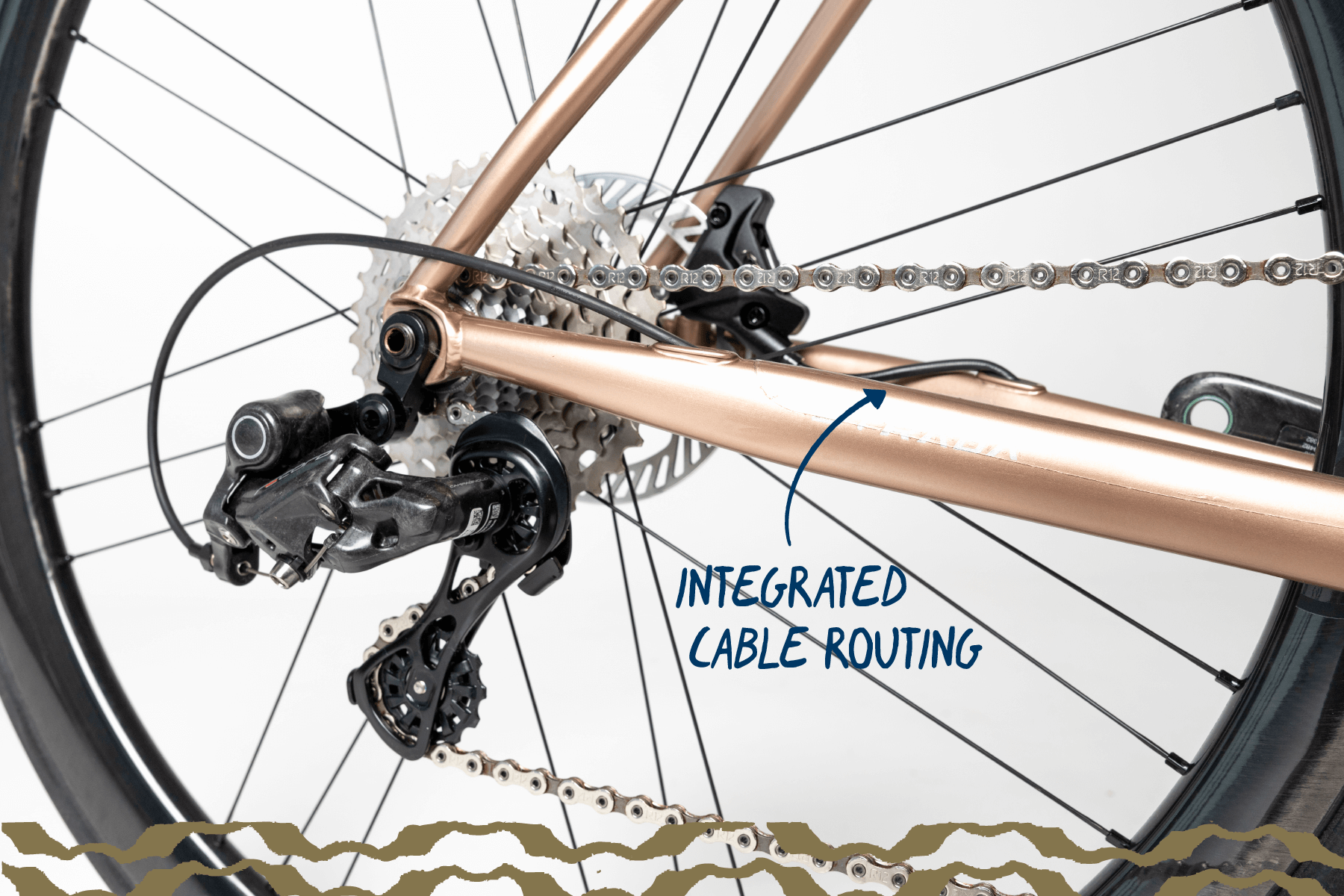

TITICI presents the AND version of ALLOI frame, which features an innovative anodizing treatment with silver ions in collaboration with GHA. Thanks to this patented technology, the frame becomes extraordinarily resistant to scratches and abrasion, guaranteeing almost total resistance to oxidation even in a marine environment. The ALLOI frame is the result of an exclusive collaboration with the Italian company DEDACCIAI, world leader in aluminium tubing. Characterized by hand-welding and integrated cable routing, this frame stands out for reliability and high stability. The new AND version enhances the strength properties that make ALLOI perfect for long adventures on dirt tracks and unpaved roads.

How it works

Thanks to a special treatment, the aluminium frame undergoes a profound surface transformation using the unique combination of anodic oxide and the noble metal Silver. As a result, a brand new material in created. The electrolytic process of anodizing causes an accelerated growth of the protective oxide layer on the aluminium. This treatment generates a new skin for the metal, characterized by very strong adhesion to the base. Silver ions seal the microporosity of the oxide, giving the surface of the frame unique properties.

The advantages

Compared to conventional painting, the AND frame has a lower weight, very high corrosion resistance and high surfaces hardness. This translates into extraordinary resistance to scratches, abrasion and wear. The coloring penetrates deeply and fixes itself in the oxide layer, guaranteeing almost infinite durability. Unlike traditional painting, no parts of the paint will detach as a result of shocks or vibrations thanks to the non-removable characteristics of the anodic oxide layer. Maintenance is easier as dirt cannot stick to the surface. Cleaning the frame after muddy or dusty ride in quick and easy.

New PAT.H. Anti-Vibration Technology

The ALLOI AND frame is realized with the top tube featuring the new PAT.H (Plate Absorber Technology Hydroformed) technology, derived from the patented PAT system available on TITICI carbon frames. The iconic shape with an oval section, which is thinner and flatter, increases the vibration damping capacity while maintaining high resistance and torsional rigidity. The top tube is given this shape through hydroforming, a technique also used in the production of sports cars that exploits the high pressure of liquids to create extremely reliable and resistant tubes. The benefits of PATH.H technology are superior stability and comfort combined with high performance. Vibrations generated by uneven terrain are absorbed by the frame structure and do not reach the rider’s arms, neck and back, the areas typically subjected to the most stress, thus leading to a greater feeling of well-being in the saddle over long distances.

ALLOI x INGRID LE – Handmade in Italy combination with INGRID components

INGRID is the fusion of different professionalisms of its creators; designers and engineers with 20 years of experience in product design and a great passion for 8 tubes. They design and produce bike drivetrains with the aim of offering a niche alternative, working on build quality, reliability and functionality. The use of materials leans towards machined aluminium, rediscovering the charm of the builders of the 80s/90s, but with current style and advanced research into structures and lightness. Features that match perfectly with the TITICI vision of the ALLOI AND project, created starting from custom Dedacciai tubes, hand-welded and anodized completely in Italy. To make this combination perfect, we chose the CRS-POP HARD ANODIZED crank with a good stiffness-weight ratio and reliable. This products is characterized by the “sponge structure” visible on the both sides, with special dots that create a pattern uses by one of the most important pop artist, Roy Lichtenstein. To complete the bike we add the INGRID 11-44 12v cassette.

HARD ANODIZATION (thick hard anodic oxidation) aims to give aluminium high resistance to wear and abrasion. This is a transformation of the surface of the crank arm into aluminium oxide and not just a surface coating. As a conversion, the layer that forms penetrates half inside and half grows outside the component, developing regularly over the entire surface of the piece, also giving it rough color and perfectly matches the anodization of the frame.

A perfect combination of Italian creativity and know-how!

Columbus x TITICI - Heart of Metal

Columbus x TITICI – Heart of Metal

Read the Columbus’ interview to Matteo Pedrazzani, TITICI Product Manager. Discover more about road model Strada, Progetto Sessanta and the collaboration with Columbus technicians.

Eurobike Frankfurt here we come!

Eurobike Frankfurt here we come!

During the fair, we will present our new TITICI bicycle collection, which stands out for its technological innovation, attractive design and superior performance. We will be happy to show the new models and to discuss the unique characteristics of each product to the cycling industry people.

Some models have already been presented through the launch on social media, such as the new Vento and the Strada and Sterrato steel frames, while we will have 2 absolute novelties, both carbon monocoque frames, one is the road aero version with stunning design, the ALFA model and the second a gravel all-round, the REVO, equipped with the new Sram Apex AXS group set.

We will wait for you at Hall 11 Stand D11!

ALFA

ALFA, like the first letter of the Greek alphabet α, symbol of ‘beginning’. The beginning of a new era of hypersonic design and disruptive innovation of current aerodynamic standards.

Since 1961 TITICI has been synonymous with Italian genius and avant-garde spirit. Our philosophy requires us that each new model represents a real innovation, something that did not exist before. From this tradition of innovating comes a new standard of aerodynamics applied to speed, the ALFA project.

ALFA represents our fastest racing bike ever, born starting from the brand new PAT10 tube, which pushes the boundaries of the possible thanks to a triple approach: unprecedented aerodynamics, exceptional ride quality and design characterized by fluid shapes. This racing bike is equipped with the unprecedented DAC TECHNOLOGY, which offers the maximum advantage in terms of speed, stiffness and comfort.

A racing bike with unprecedented aerodynamics!

REVO

REVO represents our All-round gravel carbon bicycle, with a functional and compact design, built around the new monocoque PAT10 tube, to be used for training or competition, solo travel or for outings close to home with friends.

The REVO frame is made of monocoque carbon, compatible with single chainring groupsets or with double crankset, both electronic and mechanical, and offers exceptional versatility and flexibility to cyclists who choose it for their off-road adventures.

A gravel bike with no limits!

VENTO

The new VENTO, the TITICI lightweight climbing bike, now UCI legal. Starting from 1961 we always fight to introduce new innovation in function and design, using the Italian creativity. We never stop in front of rules or competitors’ comments. But when the UCI changed the dimensions tubing for the road bike frames, we understood that maybe the Swiss technicians found our PAT so interesting that should be make legal.

We worked hard on the existing PAT, new shape, new lamination, new carbon blend and, after 2 years, we are proud to launch the new PA , now 10 mm thick to the new Vento.

Handmade to measure in Italy, entirely customizable from geometry down to paint job , extraordinarily pleasant to ride: both on the legendary Alpine passes and on the fast stretches on the flat.

Less weight, more stiffness, same comfort! A new era for your road riding experience!

Progetto Sessanta - Steel is real

S like SESSANTA, the years of life of TITICI.

S for STEEL, in English, a noble material rich in history in the bicycle frame production sector.

With PROGETTO SESSANTA, TITICI wants to celebrate the heritage of steel processing, revisited in a modern key. Tradition and technology, art and Italian craftsmanship of a material that for decades has been skillfully worked at the Castelnuovo di Asola plant, to create hand-welded frames and shipped all over the world, before being set aside for more modern materials such as aluminum, titanium and carbon fiber.

In recent times, steel has been rediscovering a new life, above all thanks to the growth of the gravel and adventure bike segments, which prefer frames made with this material, robust, soft and alive, which speaks to the frame builder who builds it and to the cyclist who uses it.

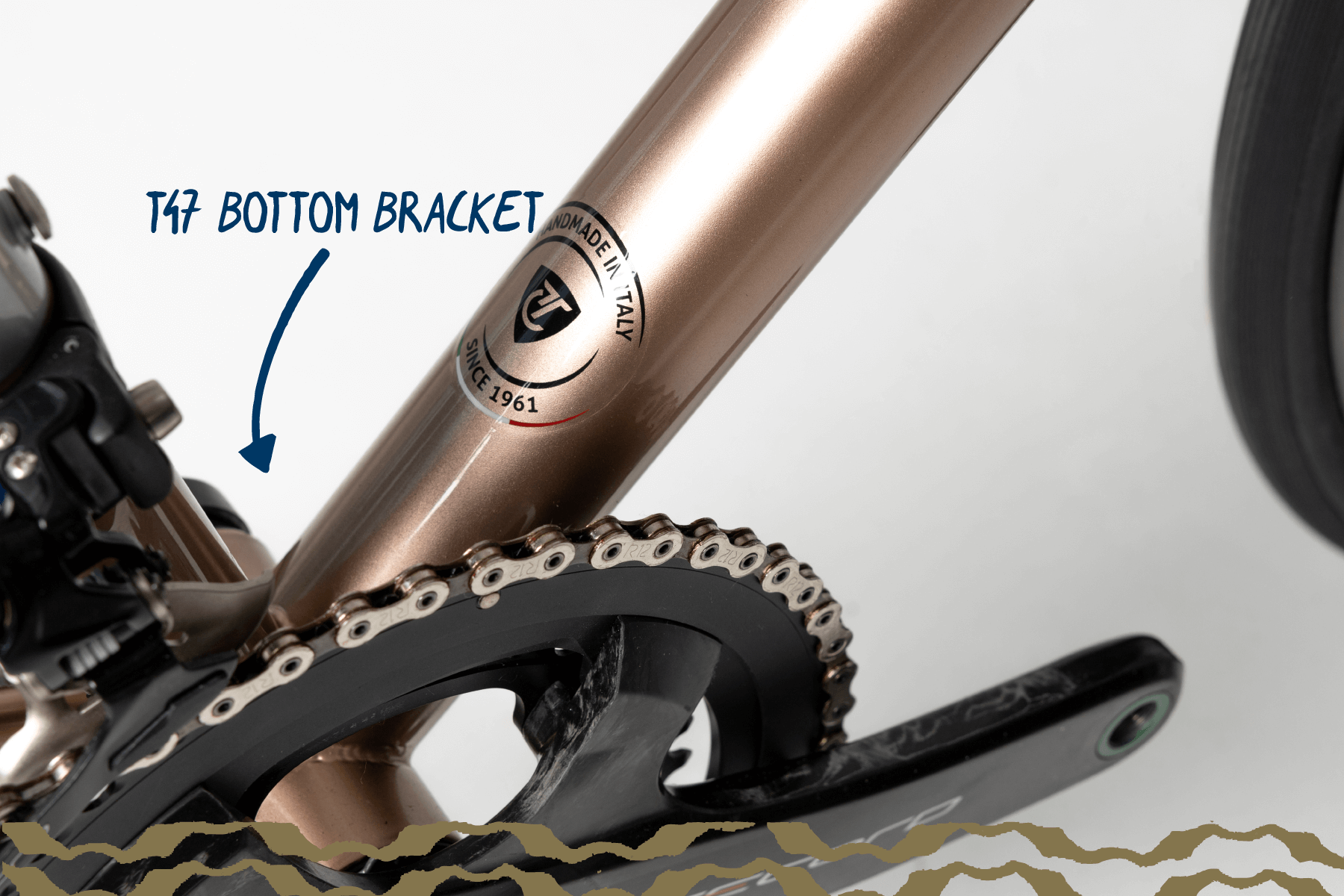

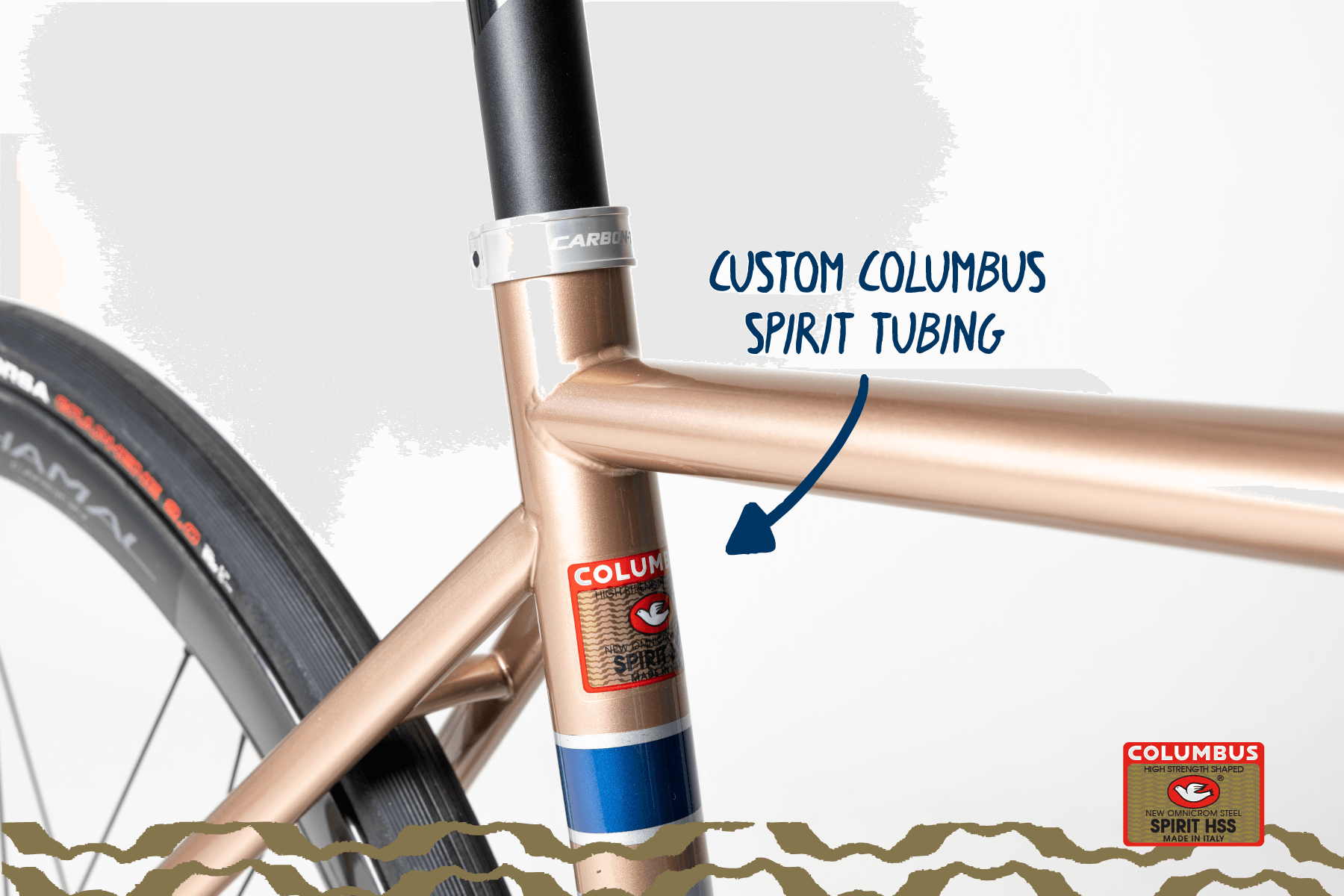

PROGETTO SESSANTA makes it possible to revive an entirely “Made in Italy” collaboration with Columbus, the historic company from Caleppio di Settala (Milan), world leader in the production of high-end steel tubes for craftsmen and frame makers, preferential supplier of the noble material for many years.

The PROGETTO SESSANTA is the result of two years of development and work between the TITICI engineers and the Columbus technicians, to produce special exclusively designed tubes, to be used for the construction of a specific frame for gravel, called STERRATO, and one for the road segment, called STRADA.

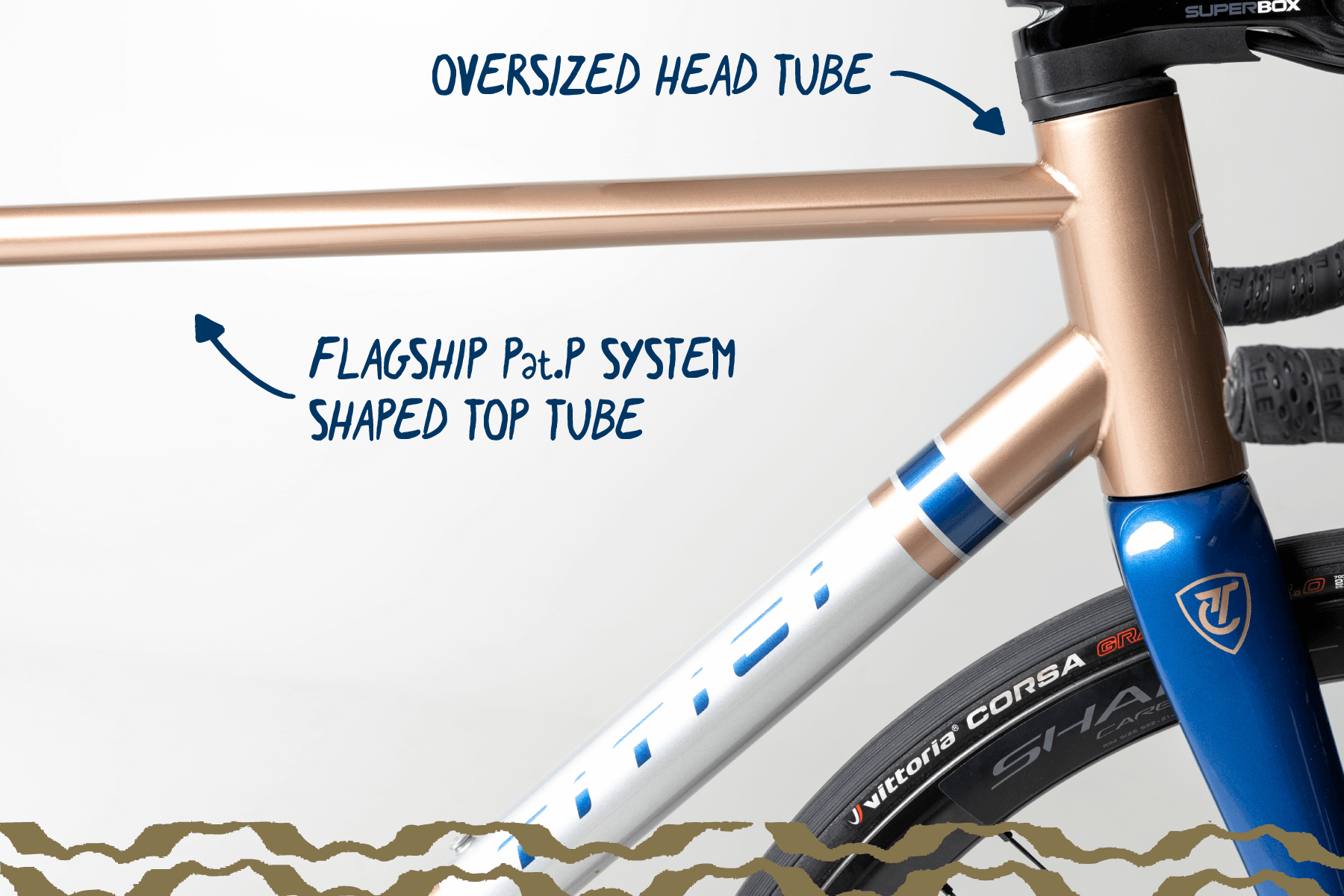

In particular, the top tube presents the classic TITICI shape of the PAT (Plate Absorber Technology) system used on carbon frames, which in the case of steel is completed in PAT.P (Plate Absorber Technology Pressed). The flat and thin shape of the flattened tube helps to reduce vibrations without compromising the rigidity and frame performance.

STRADA and STERRATO, the perfect union of Italian tradition and innovation.

Titici Alloi, an endless adventure

The Italian brand introduces the third generation of the Dedacciai aluminium gravel model designed for bikepacking and fun on dirt roads. With new PAT.H. system for vibration damping and superior riding comfort

In 2020 TITICI presents the A-GR01, its first gravel model with Dedacciai aluminium frame. The following year from the hub of Asola (Mantua Province, Italy) comes ALL-IN, the evolution of the predecessor, with integrated cable routing, new frame and rear triangle geometries. Now the Italian brand is ready to launch ALLOI, the third generation in its family of aluminium gravel bikes. The DNA has remained the same: adventure, travel, fun – with no limits in terms of duration or terrain.

New PAT.H. anti-vibration technology, comfort and resistance together

Faithful to the ‘family’ tradition, the ALLOI frame also stems from the collaboration with Dedacciai, the leading Italian company that produced the highest quality aluminium tubes, with handmade welds and customised shapes for TITICI.

The main innovation concerns the top tube featuring the new PAT.H (Plate Absorber Technology Hydroformed) technology, derived from the patented PAT system available on TITICI carbon frames. The iconic shape with an oval section, which is thinner and flatter, increases the vibration damping capacity while maintaining high resistance and torsional rigidity. The top tube is given this shape through hydroforming, a technique also used in the production of sports cars that exploits the high pressure of liquids to create extremely reliable and resistant tubes.

The benefits of PAT.H technology are superior stability and comfort combined with high performance. Vibrations generated by uneven terrain are absorbed by the frame structure and do not reach the rider’s arms, neck and back, the areas typically subjected to the most stress, thus leading to a greater feeling of well-being in the saddle over long distances.

Redesigned fork for improved ride stability

Like on the ALL-IN model, the head tube features an oversized diameter of 1 1/2″ that allows for full integration of the cables. TITICI engineers have completely redesigned the fork with an accentuated asymmetry to counteract the forces produced by the braking system. The result is greater riding stability on the most technical terrain.

Made in Italy design and functionality

Designed for long off-road adventures, the ALLOI model is optimised in every aspect, from its bikepacking predisposition to the possibility of fitting generously sized tyres, up to 700c x 40 or 650b x 45, and tackling the most extreme trails with full confidence. Sophisticated details make it unique and exclusive: the chiselled and hand-painted Titici logo on the seat stay bridge and on the chainstays, the graphic pattern on the top tube that evokes the magic of dirt roads, the total customisation of the colours. A perfect union of Made in Italy design and innovative functionality that has always been the hallmark of TITICI.

Premiere at Cyclingworld Europe in Dusseldorf, available now

It is possible to discover ALLOI in world premiere at the Cycling World Europe fair in Dusseldorf, Germany, from 10 to 12 March. The new TITICI bike model is available now on the official website www.titici.com.

The e-gravel in disguise - TITICI presents DYNAMICA.

Premiering at the Italian Bike Festival in Misano Adriatico (Sept. 9-11), the Italian brand’s new e-bike with an innovative Mahle X20 drive unit. Light, compact and streamlined: a gravel bike with extra muscle power!

The new DYNAMICA gravel bike is Titici’s all-new gravel bike with grit infused into its DNA. A substantial amount of engineering research was put into the integration of the frame with the Mahle X20 system, a powerful and innovative drive unit.

DYNAMICA is a bike designed for performance: on the flat, it’s fast and light, even without assistance above 25 km/h; and on climbs or more technical sections, the Mahle X20 motor delivers power smoothly and naturally. Enjoy longer rides, more hours in the saddle, and more fun!

Compact and sleek design: as if there was even a motor.

A key aspect of the DYNAMICA is the evolution of chassis design. TITICI engineers have succeeded in creating streamlined and compact shapes, taking chassis-drive unit integration to an entirely new level.

One example is the small bottom bracket and streamlined, aerodynamic down tube designed to accommodate a 350 Wh battery (the largest offered by Mahle). The motor in the rear hub contributes to a cleaner, more harmonious aesthetic line.

PAT anti-vibration technology.

With its patented PAT (Plate Absorber Technology) design, the DYNAMICA frame is designed to handle rough terrain as well as roads. The flat, slim shape of the top tube provides a vibration-reducing effect (up to 18% more than a standard frame) while maintaining high torsional stiffness. This results in racing performance combined with increased comfort.

Redesigned fork, superior strength.

The head tube with an enlarged 1 1/2-inch cross-section allows full integration of cables for a clean aesthetic, while at the same time providing superior riding stability, especially on technical downhill sections. TITICI engineers redesigned the fork with an accentuated asymmetry to counteract the forces generated by the braking system. A particular angle is designed into the left chainstay for greater resistance at the disc brake caliper.

More stability, and more responsiveness with the new rear carriage.

The rear triangle has also been redesigned to provide an outstanding riding experience on rough terrain. Rather than joining the seat tube, the seat stays continue to engage the top tube. In a strategic area of the frame where forces are concentrated, this design creates a more stable and strong node. The shortened chainstays provide better handling, while the asymmetrical design offers more traction. The frame is designed to accommodate generously sized tires, up to 700c x 44 or 650b x 48, and tackle the most extreme trails with maximum fun.

Mahle X20, the lightest system on the market

X20 is the new drive unit from Germany’s leading automotive and smart mobility company. Weighing only 3.2 kg, X20 is the lightest hub-integrated system on the market. At the same time, power is not to be desired: with a torque of 55 Nm, pedaling is smooth and natural on any terrain. Even when speeds exceed 25 km/h, the Mahle X20 system eliminates the typical resistance felt with less advanced systems.

The 350 Wh battery is housed in the down tube, and a 172 Wh Range Extender can be added (in place of the bottle cage) to achieve a maximum range of 200 km. Smart charging allows you to recharge the battery to 80 percent in less than two hours and get back to blazing on the trails.

Premiering at the Italian Bike Festival Sept. 9-11

The new TITICI DYNAMICA Gravel will be unveiled for the first time at the Italian Bike Festival, Italy’s largest bicycle trade show, scheduled for September 9-11 at the Misano World Circuit in Misano Adriatico (RN).

Available also in Road version, delivery will begin in spring 2023. Order now.

TITICI Sterrato GRX LE en coopération avec Shimano

TITICI célèbre le gravel avec le nouveau STERRATO en édition ultra limitée : seulement 12 pièces uniques disponibles avec le groupe exclusif Shimano GRX Limited.

La marque italienne dévoile sa dernière création gravel : tubes en acier Columbus Life, fabriqués à la main en Italie, avec système anti-vibration PAT. Les 12 premières pièces sont réalisées en collaboration avec Shimano et peintes par l’artiste Luca Di Maggio.

Patrimoine et technologie, art et artisanat italien. TITICI célèbre le cyclisme gravel avec une initiative unique en collaboration avec Shimano : le nouveau STERRATO fabriqué en édition spéciale et équipé de la version limitée du célèbre groupe Shimano GRX.

STERRATO GRX LE sera produit en seulement 12 pièces qui seront peintes à la main par l'artiste et graveur milanais Luca Di Maggio, inspiré par la devise "Ride TITICI around the world". La fourche de chaque modèle évoque un pays différent dans le monde, faisant référence aux principales caractéristiques stylistiques culturelles. Le premier modèle est dédié au Japon : le Mont Fuji, le Soleil Levant, le bonsaï et la fleur de lotus se détachent en rouge sur fond blanc - les couleurs nationales.

Nouveau STERRATO – Acier a TITICI

Le projet STERRATO est né en 2018 de la volonté d'introduire dans la gamme TITICI un matériau noble, riche de l'histoire du cyclisme : l'acier. Cette vision est à la base de la collaboration "Made in Italy" avec Columbus, l'entrepris+e historique de Caleppio di Settala (Milan), l'un des plus grands et des plus célèbres fabricants de tubes en acier. Le STERRATO est fabriqué à la main à l'aide de tubes Columbus Life conçus exclusivement pour TITICI. Le tube supérieur, en particulier, est doté du système breveté PAT (Plate Absorber Technology) déjà utilisé par la marque italienne dans ses cadres en carbone. La forme plate et fine du tube permet de réduire les vibrations sans compromettre la rigidité et les performances du cadre.

Le STERRATO est le mariage sublime entre le confort, garanti par l'acier et renforcé par le système PAT, et la performance inscrite dans l'ADN TITICI. Le résultat est un modèle au caractère vintage avec des détails modernes et sophistiqués, tels que l'acheminement des câbles intégré, le tube de direction surdimensionné et les freins à disque. La célébration parfaite du gravel, un style qui évoque le cyclisme héroïque mais qui est constamment tourné vers l'avenir et l'innovation.

Groupe Shimano GRX édition limitée

Shimano a livré les premiers composants dédiés au gravel en 2019 avec le Shimano GRX. Aujourd'hui, en coopération avec TITICI, Shimano lance le GRX Limited. À sa base, GRX Limited est le groupe mécanique éprouvé à 11 vitesses de la série GRX 800, mais la finition argentée brossée et polie offre une interprétation élégante de la qualité, de la précision et de la durabilité synonymes de GRX.

L'édition spéciale STERRATO GRX LE sera disponible à partir d'octobre avec 1x11 vitesses ou 2x11 vitesses. Le modèle STERRATO, avec configuration au choix du client, sera disponible sur le marché à partir de la même date.

Un emplacement privilégié pour le STERRATO GRX LE

Les photographies de la campagne de lancement du STERRATO GRX LE ont été prises dans le cadre magnifique du Parco Giardino Sigurtà, le parc naturel situé à Valeggio sul Mincio, dans la province de Vérone, élu l'un des plus beaux parcs d'Italie et d'Europe. L'emplacement choisi est le Laghetti Fioriti, entouré de nénuphars et d'érables japonais. Le cadre oriental fait allusion aux paysages du Japon, soulignant le raffinement du nouveau STERRATO et la création artistique de Luca Di Maggio.

Available starting in October, online and at TITICI retailers

Titici Relli, Gravel has a new shape

The Italian brand unveils its new gravel bike with the revolutionary AAT system (Arch Absorber Technology). The special arch shape of the seat tube further reduces vibrations, offering the highest combination of performance and comfort ever achieved

A racing soul in a revolutionary body shape. TITICI presents RELLI, the new full-carbon gravel bike designed to push the boundaries of offroad cycling performance. The pursuit of maximum speed, stability, comfort and riding fun has led to a radical reinterpretation of the gravel frame with the development of the innovative AAT (Arch Absorber Technology) system. The arched shape of the seat tube helps to reduce vibrations without the need for complex shock absorbers and without compromising the high stiffness of the frame, which translates into extraordinary performance.

RELLI is the natural evolution of the F-GR02 model of the Italian brand and joins the ALL-IN aluminium model in the gravel range, completing TITICI’s offer for gravel enthusiasts of all kinds: from demanding racing to adventurous bikepacking.

ARCH ABSORBER TECHNOLOGY – REDUCING VIBRATIONS, INCREASING PERFORMANCE

In 2017 TITICI was the first brand in the world to launch the PAT (Plate Absorber Technology) system, the translation to the most sophisticated engineering level of a simple intuition: the shape of the tubes and the deformation of the materials have significant influence on the comfort perceived by the rider. The flat and ultra-thin shape (only 8 millimetres) of the top tube featuring PAT technology makes it possible to absorb up to 19% more vibrations while maintaining torsional stiffness.

Fidèles au même principe, les ingénieurs de TITICI ont poursuivi le développement et conçu le nouveau système AAT (Arch Absorber Technology) qui introduit un deuxième élément de réduction des vibrations dans le cadre RELLI. Le tube de selle a été redessiné avec une forme spéciale d'arc qui a pour fonction d'amortir les impulsions de choc entre les deux nœuds du pédalier et de la selle. De cette façon, les vibrations ne sont pas transmises directement et immédiatement du sol au corps du cycliste.

Le résultat est une perception encore plus grande du confort avec un bénéfice global en termes de performance. Sur les terrains accidentés, typiques des courses de gravier, le corps est moins fatigué: le cycliste peut pousser au maximum pendant plus longtemps.

STABLE AND RESPONSIVE

Compared to the F-GR02, the RELLI’s rear end has also been completely redesigned. Lowered seat stays (the junction with the seat tube is 30 millimetres lower than the top tube) provide greater stability on dirt roads and high responsiveness. The rear triangle and the fork are designed to accommodate wide tyres, up to 700x42c, without annoying mud accumulation.

INTERNAL CABLE ROUTING

RELLI’s front end was developed from VENTO, the road frame designed to combine aerodynamics and lightness. The oversized head tube (cross-section measures 1 1/2″ instead of the traditional 1 1/8″) provides stability and steering precision, even on the most demanding sections, and allows internal cable routing for a clean and aerodynamic design.

MADE TO MEASURE IN ITALY

The RELLI frame is made of ultra-high modulus carbon fibers using PBW (Progressive Bandage Workmaship) wrapping technique with slow resins. This process makes it possible to create frames that are perfect to the millimetre, starting from the cyclist’s anthropometric measurements and biomechanical analysis. Each RELLI bike is unique, totally customised in its geometry and colors: the ideal partner for the cyclist and at the same time the expression of his character, according to the TITICI philosophy of exclusivity. The entire production process is carried out in Italy, from design and engineering to the creation of the frames and the assembly of the final product.

Available soon, online and at the TITICI retailers.

Titici presents All-in And

Titici présente le All-in And: le nouveau cadre gravel doté d'un traitement d'anodisation ultra-résistant et d'ions d'argent.

La marque italienne dévoile à Cyclingworld Düsseldorf (Allemagne, 18-20 mars) la version AND de son cadre en aluminium ALL-IN, doté d'un traitement exclusif d'anodisation: extraordinairement résistant aux rayures, à l'abrasion et à l'usure.

Les belles choses durent éternellement. TITICI présente la version AND de son cadre ALL-IN, doté d'un traitement d'anodisation innovant aux ions d'argent. Grâce à cette technologie brevetée, le cadre devient extraordinairement résistant aux rayures et à l'abrasion, garantissant une résistance quasi totale à l'oxydation même en milieu marin.

Le cadre ALL-IN est le fruit d'une collaboration exclusive avec la société italienne DEDACCIAI, leader mondial du tube aluminium. Caractérisé par le soudage à la main et l'acheminement des câbles intégré, ce cadre se distingue par sa fiabilité et sa grande stabilité. La nouvelle version AND améliore les propriétés de résistance qui rendent le ALL-IN parfait pour les longues aventures sur les chemins de terre et les routes non pavées.

HOW IT WORKS

Grâce à un traitement spécial, le cadre en aluminium subit une profonde transformation de surface grâce à la combinaison unique d'oxyde anodique et du noble métal qu’est l’argent. En conséquence, un tout nouveau matériau est créé.

Le processus électrolytique d'anodisation provoque une croissance accélérée de la couche d'oxyde protectrice sur l'aluminium. Ce traitement génère une nouvelle peau pour le métal, caractérisée par une très forte adhérence à la base. Les ions d'argent scellent la microporosité de l'oxyde, donnant à la surface de la monture des propriétés uniques.

THE ADVANTAGES

Par rapport à la peinture conventionnelle, le cadre ALL-IN AND a un poids inférieur, une résistance à la corrosion très élevée et une dureté de surface élevée. Cela se traduit par une résistance extraordinaire aux rayures, à l'abrasion et à l'usure.

La coloration pénètre en profondeur et se fixe dans la couche d'oxyde, garantissant une durabilité quasi infinie. Contrairement à la peinture traditionnelle, aucune partie de la peinture ne se détache sous l'effet des chocs ou des vibrations grâce aux caractéristiques inamovibles de la couche d'oxyde anodique.

L'entretien est plus facile car la saleté ne peut pas coller à la surface. Le nettoyage du cadre après une balade boueuse ou poussiéreuse est simple et rapide.

PREMIÈRE MONDIALE AU CYCLINGWORLD DÜSSELDORF DU 18 AU 20 MARS

Le cadre ALL-IN dans la version AND sera présenté en avant-première absolue à Cyclingworld Europe (à l'intérieur du stand du concessionnaire TITICI La Bici), le prestigieux salon de la meilleure culture vélo qui se tiendra du 18 au 20 mars à Düsseldorf (Allemagne). Ce traitement peut être commandé immédiatement pour les cadres ALL-IN dans les versions Apex, Grx et Rival Axs.